Quality Management?

business disruptions.

out-of-the-box AI capability.

already in Pilot Project.

Reduce the cost of Quality and boost Customer Satisfaction.

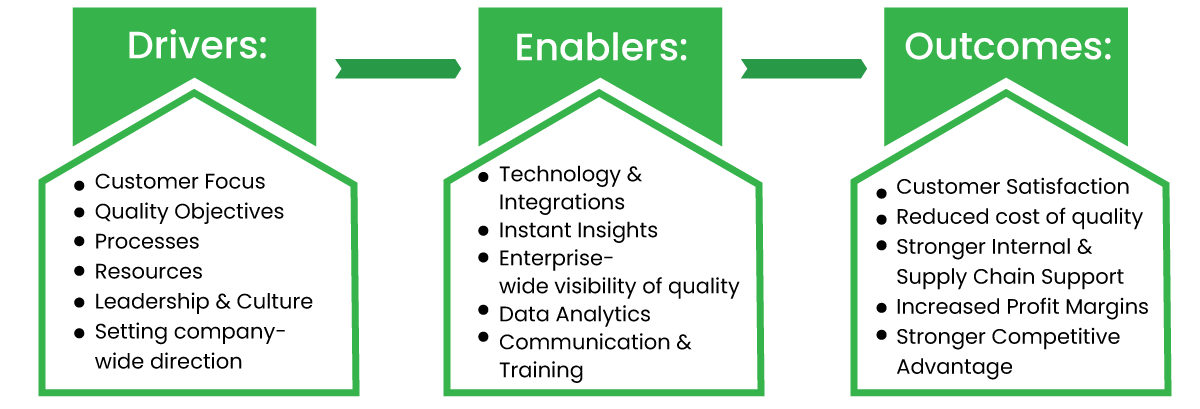

Smart manufacturers realise that consistent quality of products and services is essential to business success. Automating Quality Management is the only way to achieve consistent quality at low cost. The question that remains is how to choose the right solution.

Introduction to FactoryWorxTM Quality Management System

FactoryWorxTM Quality Management is the smartest path to automating quality and compliance processes for long-term customer satisfaction through consistent quality and delivery of products.

FactoryWorxTM Quality Management automates your quality processes with digitised recipe management and product specifications, automated controls, real-time trends, statistics, and notifications, ensuring strict adherence to quality levels and standards.

Unlike most quality management systems, FactoryWorxTM Quality Management is by default, Industry 4.0 and IIoT enabled. As one of the core modules of FactoryWorxTM MES solution, the FactoryWorxTM Quality Management module has a superior ability to connect, access and leverage data, giving you a massive competitive advantage by accelerating your operations.

FactoryWorxTM

MES ENQUIRY

Starting with automation or looking for a holistic MES Solution? Start Here.

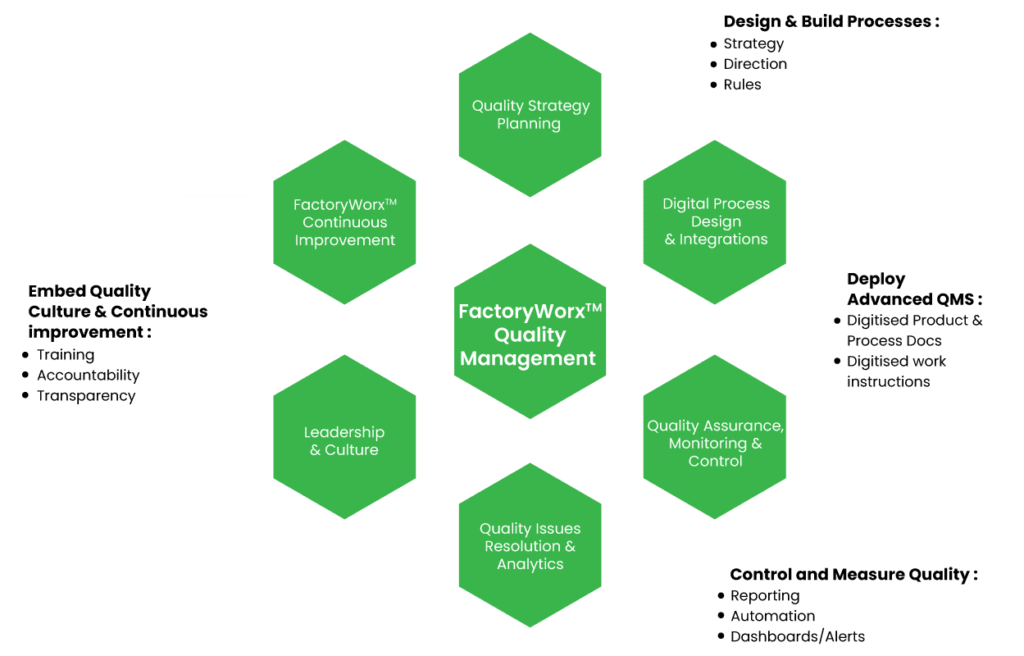

FactoryWorxTM Quality Management Process

FactoryWorxTM Quality Management software automates the process of creating and delivering consistent quality to customers.

Benefits of FactoryWorxTM Quality Management

Implementing the FactoryWorxTM Quality Management system has a positive, direct impact on every aspect of business performance. With FactoryWorx your benefits of having a digitally documented quality management system, are enhanced through automation, IIoT connectivity and integrated, scalable capabilities of FactoryWorxTM MES, Continuous Improvement and Industry 4.0 platforms.

Consistently delivered product and service quality

Increased customer satisfaction and retention

Increased efficiency and productivity

Faster response to quality issues

Reduced cost of waste in materials and rework

Reduced cost of achieving product quality

Improved compliance

Effective and automated traceability

Improved employee performance

Stronger internal support for business strategy

Attract greater supply chain collaboration and opportunities.

Stronger competitive advantage

FactoryWorxTM Quality Management – Your Path to Perfect Quality

Quality is a strategic approach through business leadership that ensures the clarity of strategy, direction and rules. FactoryWorxTM Quality Management system enables businesses to digitise and automate processes to achieve quality with efficiency.

Explore the Functionality and Benefits of FactoryWorxTM Quality Management

FactoryWorxTM Quality Management is a real-time, advanced system enabling manufacturers to automate quality processes, and manage and control documentation, workflows, training, internal and external audits, and compliance. It is ideal for compliance-driven industries, such as food, pharmaceutical, building products and mining.

FactoryWorxTM Quality Management integrates with the ERP/production Master Data system, including BOM, CAD and other product information. It tracks material usage quantity/ratio during production against the BOM.

- Digitised, single source product and process information ensures the right quality.

Instant alerts highlighting quality issues are delivered instantly via Factory Dashboards and other technologies, to operators and quality inspectors on the shop floor for action.

Extra functionality that ensures required actions are performed in a timely manner.

A variety of reporting options are available in FactoryWorxTM Quality Management as standard, to be adapted as required.

- Real-time quality checks – out-of-spec measurements, defects found

- Process Capability Indices e.g. Cp, Cpk

- Control Plan Conformance

- Analytical Insights: Pareto analysis, trends

Instant visibility of quality issues and requirements on individual, team and management level

Transparency that enhances accountability

FactoryWorxTM Quality Management software automates data capture from every step of the manufacturing process.

Instant work instructions available to operators

Ability to enforce quality control

Timely response to issues

- Continuous measuring of conformance data for future improvement

Automating traditional statistical tools to measure variations, understand process capabilities and drive improvement to reduce the impact of non-conformance.

Data driven insights for reporting and improvement

FactoryWorxTM Quality Management software automates monitoring of process parameters, using the in-built historian (an element of FactoryWorxTM MES).

- Dashboard visualisation

Deep insight into production process to maximise traceability

All work instructions and production process documentation are available as a digital Master for operators to quickly access information they need: SOPs, CAD drawings, product specifications, quality procedures and compliance requirements to ensure they work to the latest product version.

- Reduced errors from using wrong documentation

- Reduced reliance of paper copies

Saved time and cost of handling paper documentation

FactoryWorxTM Quality Management software enhances rapid resolution as well as tracking and recording non-conformance issues for future learning and improvements.

- Automatic alerts for downtime, machine cycle speeds, process conditions, and exceptions.

- Automatic message routing and escalation for specific plant conditions.

- Simple “call for help” function.

- Faster response

- Reduced downtime

- Reduced cost of waste

FactoryWorxTM Quality Management enables manufacturers to digitise and standardise the complaint handling process.

- Faster problem resolution

- Clear accountability

- Visibility of best practice

- Data analysed for improvement

Poorly performing supply chain partners can cripple your business. FactoryWorxTM Quality Management enables monitoring and resolution of issues and claims as well as drive best practice and improvement with paperless records and documentation.

- Visibility and fast resolution of issues and claims

Stronger relationship and support for mutual results

Ensuring quality of materials entering your manufacturing operations – through FactoryWorxTM Quality Management system and MES enable digitised inspection, sampling and control of incoming parts, preventing downstream quality issues and minimising the cost of poor quality.

- Reduced and eliminated waste in production

Reduced cost of inspection and quality assurance

FactoryWorxTM Quality Management system allows manufacturers to take quality assurance to the next (IIoT) level. This IIoT driven software enables manufacturers to test and inspect materials and product quality throughout the entire production process, using digitised metrics including graphic portraits of ideal view of quality. Its predictive, pre-emptive nature prevents producing defective products, reduces waste and may prevent downtime and even machine damage.

- Pre-emptive reports and actions to eliminate waste, downtime and defects

FactoryWorxTM Quality Management system enables our clients to drive Continuous Improvement. As part of our advanced MES, FactoryWorxTM Quality Management module taps into enterprise-wide BI and uses advanced data analytics as well as built-in statistical process control (SPC) and statistical quality control (SQC) to further reduce costly waste of materials and rework, while consistently meeting customer requirements.

- Automatic part qualification and rejection

- Avoid chargebacks and defect penalties by ensuring conformance to quality standards

- Further improvement of product and process quality

Increasing the competitive advantage

WANT TO KNOW MORE ABOUT QUALITY MANAGEMENT?

Check Out These Related Modules

How FactoryWorxTM Quality Management Supports QMS Standards

FactoryWorxTM Quality Management system supports official industry standards that govern your industry. Our digitised, IIoT driven, paperless quality system enables any organisation to deploy systems such as ISO 9001:2015, the most recognized and widely implemented quality management system standard in the world, by digitally aligning ISO 9001:2015 requirements for a QMS with their own customised programs.

This applies to other quality management standards in the ISO 9000 series (e.g. ISO 9000 and ISO 9004), the ISO 14000 series (environmental management systems), ISO 13485 (quality management systems for medical devices), and ISO/TS 16949 (quality management systems for automotive-related products).

Deploy FactoryWorxTM Quality Management on Your Terms

One of the most valued benefits of FactoryWorxTM MES modular solutions is flexibility. If you are not ready to go full throttle into Industry 4.0 transformation, you can easily adopt the complete FactoryWorxTM Quality Management or roll it out one functionality at a time. Both options are equally viable depending on your situation and needs.

Each Module is an independent mini-MES Module that enables deploying automation and efficiencies where they are most needed.

If you choose to get a DEMO to see FactoryWorxTM Quality Management in action, our expert will show you the best way to address your most challenging or annoying manufacturing issues.

DEPLOYMENT OPTIONS:

- Cloud – SaaS, Web-based

- Desktop – Mac, Windows, Linux

- Mobile – iPhone, Android, iPad

- On-Premises – Windows, Linux

PRICING OPTIONS:

- Free Trial

- Monthly Subscription

- Annual Subscription

- One-Time License

SEE THIS SOLUTION IN ACTION!

Discover how FactoryWorx can help you achieve perfect product quality every time.

WHAT IS YOUR KEY MANUFACTURING CHALLENGE?

We Have the Solution

Fully optimised production planning, visibility, control.

Measure and gain instant real-time insight into important data.

Automated, instantly measurable quality across a matrix of factors.

Instant visibility of component and product status, quantity and location.

Seamlessly integrates with major ERP and known business systems.

Industry 4.0 enabled, real time production environment visibility.

Control product progress/cost from components to despatch.

Faster, always accurate and reliable digital factory operations.

Lean starts with no down-time preventative maintenance.

Just plug in and action insights to reduce cost and your footprint.

Optimise yield on equipment and stock for maximum

Empower people to see the bigger picture, their progress and support.

FREE TRIAL

Test FactoryWorx Core Modules in Your Operations

Try Before You Buy. Adopting new, advanced MES, Manufacturing Execution System, whether as a single function or entire Industry 4.0 transformation, is a major business commitment. It’s not just cost, but also potential disruptions, increased workloads and a steep learning curve. Not with FactoryWorx!

Energy Management

production Planning

OEE Reporting

Manufacturing Dashboard

See the Simulation first in a Personalised DEMO.

Take the Next Step Towards Manufacturing Excellence

The biggest difference to your outcomes depends on what you do next.

Choosing the best MES solution for your manufacturing operation is easier than you think. FactoryWorx modular, scalable MES platform can rapidly transform manufacturing your company into an Industry 4.0 leader. Scalable for growth and offering exceptional value, FactoryWorx is the number one choice for some of the leading brands as well as small manufacturing operations.